The Hidden Journey Of A Custom Fixture

Understanding the Vision

Every custom lighting fixture starts with a conversation. Before we ever touch a tool, we take the time to understand the full picture: the client’s vision, the aesthetic of the space, and the functional role of the fixture. But we don’t stop at surface-level intent we speak the language of every stakeholder involved. That means translating between architects, lighting designers, and contractors to align goals, eliminate miscommunication, and ensure the fixture fits into the broader project ecosystem without friction.

From Concept to Buildable Design

With a clear direction, we move from idea to implementation. Whether we’re starting with a napkin sketch or a fully modeled concept, we translate design intent into a fully engineered solution. This includes selecting mounting methods, specifying wiring, addressing weight and structure, and making sure everything is compliant with electrical and safety codes. Our goal is always the same: to preserve the creative vision while ensuring the end result is buildable, reliable, and cost-effective.

Prototyping When It Adds Value

Not every fixture needs a prototype but some do. When a physical sample will help clarify form, material behavior, or assembly, we build and test one. It gives clients and designers the chance to see and feel what’s coming to life. But we don’t prototype for the sake of it. When the design is clear and the path forward is proven, we move straight into production, saving time and resources. Our process stays lean and responsive to the needs of each project.

Smart Material Choices

Materials aren’t just a design decision, they’re a performance decision. We help clients select metals, finishes, diffusers, and coatings that not only look great but also hold up to heat, cleaning, wear, and time. We balance cost, durability, availability, and lead times. Whether the goal is luxury, utility, or both, we guide decisions that serve both the design and the bottom line with full transparency at every step.

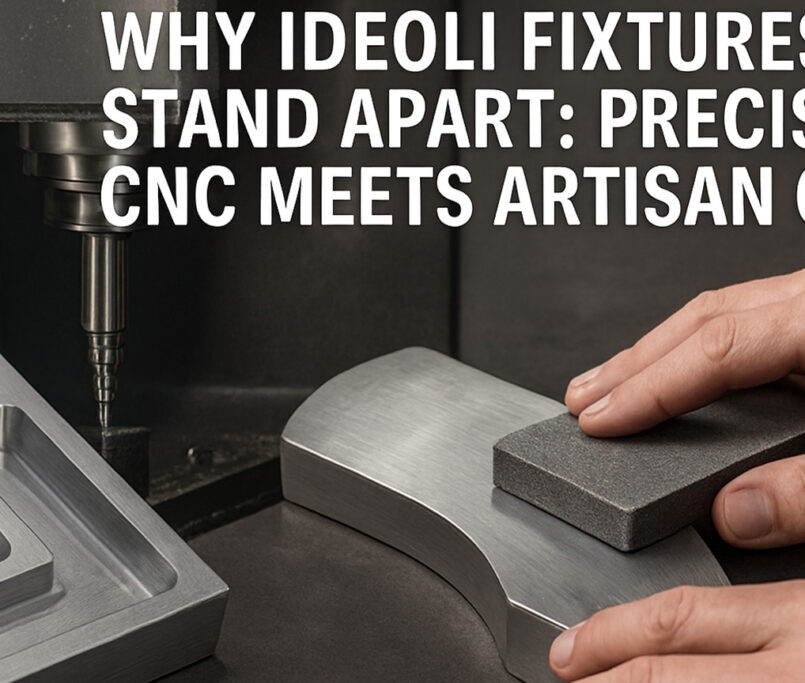

Manufacturing and Communication

Once materials and specs are locked in, we move to fabrication. Every fixture is custom-made to order, and our shop is set up for precision and repeatability. As the build progresses, we maintain open lines of communication with the client providing status updates, confirming milestones, and flagging any adjustments early. No one’s left in the dark. Our proactive approach keeps everything moving and minimizes surprises.

Certifications and Shipping

Navigating safety certifications and logistics is part of the job. Whether it’s UL, CE, ETL, or a specific project requirement, we manage testing, documentation, and approvals. When it comes time to ship, we coordinate packaging, freight, and customs (if needed) to ensure fixtures arrive undamaged and on schedule whether it’s going across the country or across the globe.

Support Through Installation

Installation shouldn’t be stressful. We provide detailed documentation, install guides, and wiring

For more insights and updates, don’t forget to follow us on social media and let’s spark some creativity together! LinkedIn Facebook Instagram Twitter YouTube